Description

What to DryScreen printing conveyor dryer (also known as tunnel drying ovens or IR/hot air drying tunnels) are key equipment in screen printing processes, Their main purpose is to rapidly cure and dry inks, coatings, or adhesives on printed products through controlled heating (infrared, hot air, or a combination of both) and continuous conveyance.Their core value lies in enabling continuous, large-scale, stable, and highly efficient production, making them essential equipment for upgrading the screen printing industry from manual workshops to automated manufacturing.

Infrared conveyor tunnel dryer effectively solves many problems which has long beset the utilization of this process,such as,discoloration of printed cloth, the difficulty of fully drying heating-set ink,etc.

Our IR conveyor tunnel dryer is an all-in-one conveyor dryer designed for heating printing inks (plastisol and water-based inks)on t-shirt ,textile,bags,etc, It uses the latest technology, is easy to operate, and affordable. Elevate your print quality and boost production with Solutions — the choice of professionals worldwide!

our conveyor tunnel dryers provide continuous, controlled heat to fully cure plastisol inks(heating-set inks) on garments and fabrics, ensuring colorfastness, durability, and stretch resistance,enables the production of printed products with good colorfastness,high flexibility and high gloss.Ideal for high-volume prints shops that need sped and consistency.

Product VideosWe can supply using videos and installation videos,you load down them from youtube.

Stronger Panels, Smarter Design

Stronger Panels, Smarter Design

Welcome to a seamless start with your new screen printing equipment from PRINTVS. We believe that powerful machinery should be accompanied by equally powerful support. That’s why we provide an extensive library of high-quality, step-by-step video guides for every machine we sell, ensuring you can unbox, install, and operate with complete confidence from day one.Go beyond the manual. Our videos provide clear, practical demonstrations of your equipment’s key functions. Learn the nuances of loading pallets, achieving perfect registration, mastering print strokes, and performing routine maintenance. These tutorials are designed to help both beginners and seasoned printers achieve flawless, consistent results.

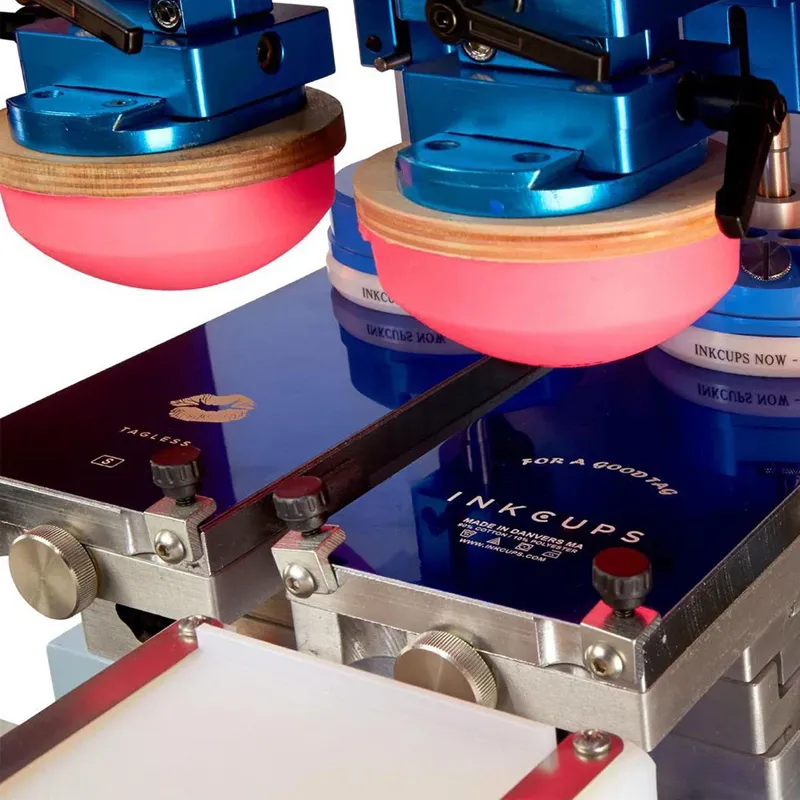

Upgrade Your IR Conveyor Dryer Tunnel

Larger Heating Zone(40″x42″)This conveyor dryer have larger heating oven, ensure the clothes is in the state of imperial spread through hetaing chamber,it can fully dry the inks on clothes,larger heating oven can dry larger printing area, and improve the drying efficiency.

Adjustable Belt Speed & DisplayEquipped with digital belt speed controls and display,accurate and variable belt speed,allowing for optimal curing times specific to various inks and materials.

IR Heater with Reflective Coating6 IR heating tubes(Power: 800w/pc) with reflective coating,heating rapidly and even.Same time, users can adjust distance between IR heating tube to conveyor belt, allowing for flexibility when curing a variety of items, including t-shirts and bags,etc.

Digital Temperature Control Adopts digital temperature controller(accuracy: +/- 1º),there is a temperature prob in chamber,users can easily set and adjust the temperature to ensure effective curing for different types of ink and materials.more efficient.

Conveyor Belt with Guide BarThe 30-inch wide teflon conveyor belt is with guide bar,ensuring smooth operation and minimizing the risk of sticking. 2 big rollers with guide trough to guarantee run straight,never position offset.Hassle-free belt tracking guide

Quick Assembly and Space-SavingThe unit comes approximately 90% pre-assembled, simplifying setup to just 30 to 45 minutes. our conveyor dryer tunnel combines space-saving design with professional-grade durability, Ideal for high-volume prints shops and studio

Precise and Stable Registration Every TimeYou can print your images on t-shirts freely,colorful and beautiful.

One Color Images Printingyou can save labor and space if just print one color

6 Color Images PrintingMax 6 colors silk screen printing,enough for 90% jobs

Complex Images PrintingPrecise registration device suitable for complex images

The conveyor dryer is one of the best options for a starter conveyor available on the market. It offers many features that standard conveyor dryers don’t typically have and its build to last. This dryer is a great addition to a small shop or package that only has a flash dryer for an infrared heating source. Also the oven portion of the dryer is completely adjustable to accommodate different needs and different jobs. By moving the oven back on the belt you can actually fit more shirts in the dryer at a time. Also the locking casters on the base of the dryer allow for easy storage and mobility. Start off on the right foot with the right dryer for your growing business!

This crate will weigh over 200 lbs and, unless you have a loading dock or forklift, you will need the delivery truck to come with a lift gate.

Fully Insulated Heating Oven with VentLarge area(40″x42″) double wall insulation heating oven with with galvanized interior. air circulation vent in center of oven top, users can adjust the internal airflow circulation pattern by covering or uncovering the vent to meet different heating process requirements.

Besides, users can take off heat oven easily when adjust the height of heating tubes.

Larger Heating Zone(40″x42″)This conveyor dryer have larger heating oven, ensure the clothes is in the state of imperial spread through hetaing chamber,it can fully dry the inks on clothes,larger heating oven can dry larger printing area, and improve the drying efficiency.

Digital Control Box For Speed & TemperatureAdopts digital temperature controller(accuracy: +/- 1º),there is a temperature prob in chamber,users can easily set and adjust the temperature to ensure effective curing for different types of ink and materials.

Equipped with digital belt speed controls and display,accurate and variable belt speed,allowing for optimal curing times specific to various inks and materials.

Teflon Conveyor Belt with Belt Tracking Guide

The 30″ wide high-temperature teflon conveyor belt is with guide bar,two heavy-duty conveyor rollers with hassle-free belt tracking guide,ensuring smooth operation and minimizing the risk of sticking,never position offset.

6 IR Heating Tubes with Reflective Coating Six high quality heating tubes compose the heating panel,the total power is 4800W(800w/heating tube), every tube coat the reflective to improve drying efficiency.IR heating tube is especially suitable for solidifying heat-set and special type of printing ink.Same time, users can adjust distance between IR heating tube to conveyor belt, allowing for flexibility when curing a variety of items, including t-shirts and bags,etc.

Brand AC Motor with Chain Wheel

equipped with brand Industrial grade AC motor as conveyor system, variable frequency AC Motor can be set to different speed,runs the conveyor rollers smoothly and even by chain wheel, very stable and long lifetime.

Adjustable Belt Tracking and TensionConvenient bolt adjustments at the exit end make it easy to track and tension the belt as needed.

Adjustable Infeed/Outfeed Doors

Users can adjust Infeed/Outfeed Doors’ height by the red knob according to different needs and different jobs.

Quick Assembly and Space-SavingHeavy-duty multi-section construction with power coated steel,easy to assemble

The unit comes approximately 90% pre-assembled, simplifying setup to just 30 to 45 minutes. our conveyor dryer tunnel combines space-saving design with professional-grade durability, Ideal for high-volume prints shops and studio

Smart assembly design to save packing volume and shipping cost.

Parameter

Infeed length: 500 MM

Outfeed length: 500 MM

Heating oven length: 1000 MM

Conveyor tunnel length: 2000 MM

Conveyor belt witdth:750MM

Heating tube quantity: 6 Pcs

Total power: 4.8 KW

Temperature adjustment: 0-300 Centigrade

Belt speed adustment: 0-300CM/MIN

Packing size: 1230x1110x1200mm

Gross weight: 280 KG

Warranty: 3 years(except heating tubes)

Special size and color can be customzied

Shipping Machines & Supplies to Customers WorldwideWe will pack the goods in good condition before shipping, ensure that the goods arrive in perfect condition after long-distance transportationu003cbru003eHere are some real scenes of the shipment and packaging process.

Export screen printing machines to Spain

Export 24u0022x32‘’ exposure units to UK

Export 6KW flash dryers to amazon warehouse

Export IR conveyor tunnels to Germany

Printvs’Certification

Why Choose Printvs as Screen Printing Machine SupplierOur silk screem printing products have superior performance, strong reliability, and have been widely used in China and other countries and regions in Asia, America, Australia, Europe, Africa, and won the user high praise from users.

Machine Quality

After Service

Factory Scale

Prefect Warranty

Technical Support

Company Honor

Exhibitor at International Trade Shows/Fairs/ExhibitionsPrintvs take part in internaltional shows/exhibitions for many years

Exhibitor

Exhibitor

Exhibitor

Exhibitor

Exhibitor

Exhibitor

Exhibitor

Exhibitor

FAQs:

Q: How to choose a screen printing machines or other equipment?

A: You choose the screen printing machines according to your images,if your image have 4 color, you should choose the 4 color screen printing machine, if you want to improve the efficiency, you can buy flash dryer together.

Q: How about the installation?

Q: How about your delivery time?

Q: What about after-sale service?

Q: What mode of payment do you usually accept?

Q: How long is the warranty period for your equipment?

Q: How to choose the shipping way

Q: Do you customize aluminium frames or making screens

Q: How to choose the rright silk screen mesh size

Q: How to choose a screen printing machines or other equipment?

A: You choose the screen printing machines according to your images,if your image have 4 color, you should choose the 4 color screen printing machine, if you want to improve the efficiency, you can buy flash dryer together.