Description

What to Dry or StorageThese metal drying racks are designed to dry and store works-on paper-flat in the studio and prints shop. Sprung shelves can be lifted and held in position. Perfect for editioning, they are available in standard and custom sizes. The frame colour can be customised and the steel racks powder-coated or zinc-plated to protect them. wheels enable the units to be easily moved around the studio.

Our screen printing drying racks is designed specifically for silk screen printing, The Drying rack is used for drying screen prints without smearing, in room air or in a heat chamber.this rack accommodates various screen sizes and drying requirements, The drying racks is a auxiliary equipments,this screen drying racks are suitable for storing prints,paintings, metal name plate,screen or pad printed products or thoer flast substrates,you can put t-shirts,film,screen plate.etc on it to dry in nature or in heat chamber,it is very convinient and save space.enhancing workflow efficiency for printers of all levels.

Product VideosWe can supply using videos and installation videos,you load down them from youtube.

Stronger Panels, Smarter Design

Stronger Panels, Smarter Design

Welcome to a seamless start with your new screen printing equipment from PRINTVS. We believe that powerful machinery should be accompanied by equally powerful support. That’s why we provide an extensive library of high-quality, step-by-step video guides for every machine we sell, ensuring you can unbox, install, and operate with complete confidence from day one.Go beyond the manual. Our videos provide clear, practical demonstrations of your equipment’s key functions. Learn the nuances of loading pallets, achieving perfect registration, mastering print strokes, and performing routine maintenance. These tutorials are designed to help both beginners and seasoned printers achieve flawless, consistent results.

Upgrade Your Screen Printing Drying Racks

Split-Combination StructureThe main body of the drying rack is composed of two independent joinable parts(Baseplate and Back support bracket), It is simple to put together with the included baseplate and back support bracket. quick and easy to assemble, prevent damage in delivery,and save freight.

50 Shelives (26″x36″) Net shelf size: 26″x36″ (65x92cm)

Shelf quantity: 50 layers

layer gap: 1″ (2.54cm)

All trays are countersprung for smooth operation

Ideal for small studios and busy print shops,it provides reliable, professional results every time.

Versatile Use Design with WheelsThe screen printing drying rack accommodates various screen sizes and drying requirements,are suitable for storing prints,paintings, metal nameplate,screen or pad printed products or other flat substrates,move freely with 4 wheels.it is very convenient and save space.enhancing workflow efficiency for printers of all levels.

Heavy Duty shelives with hooks Each welded shelf consists of round 3 mm and 5 mm crossbars,and each shelf have 2 hooks for springs,fully shelives galvanized,long-term use without rust,ensures longevity and stability while providing excellent support for freshly printed screens, significantly reducing the risk of damage.

Flexible Plastic Spacer PadsWe specially developed molded plastic spacer pads,Easily dismantled and reassembled on site.reduce noise when using.we can take off them from shelives before shipping, then pack the shelives in regular carton with good protection.reducing the risk of damage in delivery

Adjusted Springs & Limited sheets Two springs hold each shelf in an elevated position.The spring hooks prevents the spring from slipping out,more safety,you can adjust the tension by bolts, opening angle of 45° throughout for all trays because of 2 pc limited sheets(45° angle)

Say Goodbye to Traditional Drying Rack Problems.Our new design perfectly solves the problems of traditional drying racks.

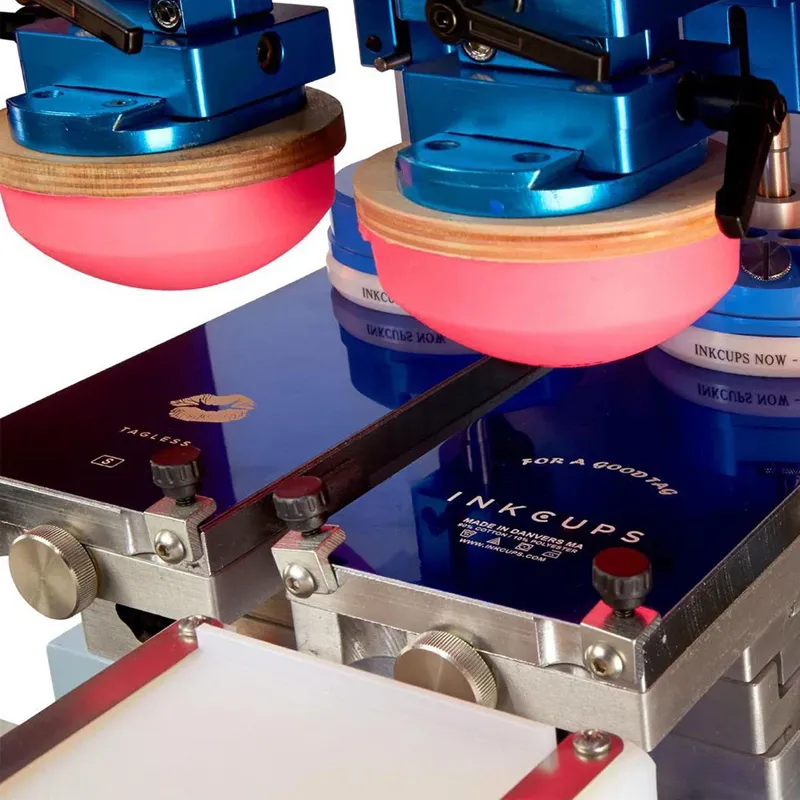

One Color Images Printingyou can save labor and space if just print one color

6 Color Images PrintingMax 6 colors silk screen printing,enough for 90% jobs

Complex Images PrintingPrecise registration device suitable for complex images

Usually, the traditional drying rack are not easily to be shipped, and easily be knocked, deformed, the surface of the rack wear out badly. Our dryingtrack is combined type, shipping easily and security.

According to the problems, we designed one new model, The main body of the drying rack is composed of two independent joinable parts(Baseplate and Back support bracket), It is simple to put together with the included baseplate and back support bracket. we pack the main body(after diassembly) with foam to protect the surface of it in delivery.

About the traditional net shelives, every shelf have to weld metal spacer pads,and these metal spacer pads can’t be removed, it’s very noise when using ,and it’s very difficult to pack shelives in regular carton, have to pack the shelives very simply, so the shelives are damaged in delivery,and waste shipping cost. compared with traditional racks,We specially developed molded plastic spacer pads, you can take off them before shipping, just pack the shelives in regular carton with good protection. you install the plastic spacer pads when installing drying rack, very easy to assemble. it isn’t noise because of plastic spacer pads when using this rack.

Through the innovations mentioned above, we have solved the long-standing problems that have plagued traditional drying racks for years.

Split-Combination Structure For ShippingThe main body of the drying rack is composed of two independent joinable parts(Baseplate and Back support bracket), It is simple to put together with the included baseplate and back support bracket. quick and easy to assemble, provides good packing in delivery, and save shipping cost

Heavy Duty shelives with springs hooksEach welded shelf consists of round 3 mm and 5 mm crossbars,and each shelf have 2 hooks for hanging springs,fully shelives galvanized,long-term use without rust,ensures longevity and stability while providing excellent support for freshly printed screens, significantly reducing the risk of damage.

50 Galvanized Shelives (26″x36″) Shelf size: 26″x36″(65x92cm)

Shelf quantity: 50 layers

layer gap: 1″ (2.54cm)

All trays are countersprung for smooth operation

Ideal for small studios and busy print shops,it provides reliable, professional results every time.

Flexible Plastic Spacer Pads

We specially developed molded plastic spacer pads(2.54cm thickness),one spacer pads is composed of two modules, upper modules and lower modules,Easily dismantled and reassembled on site.reduce noise when using.we can take off them from shelives before shipping, then pack the shelives in regular carton with good protection.reducing the risk of damage in delivery.

High Quality Springs with Adjustabe Bolts Two springs hold each shelf in an elevated position.The spring hooks prevents the spring from slipping out,more safety,you can adjust the springs’ tension by bolts, very durable and stable.

2 Limited Sheets on Top 4 Wheels on Bottom

There are 2 limited sheets on the top, opening angle of 45° throughout for all trays because of 2 pc limited sheets(45° angle)

There are 4 universal wheels,enable the racks to be easily moved around the studio.

Huge Packaging Transportation AdvantagesCompared with traditional drying racks, the new design offers significant advantages in packaging and transportation. Traditional drying racks are difficult to package properly due to structural limitations, often leaving them exposed or only loosely wrapped. This frequently leads to issues such as mesh deformation, surface scratches, or damage during transit. Additionally, their bulky size substantially increases transportation costs, resulting in considerable resource waste.

The new design fundamentally addresses these long-standing transportation challenges through optimized structure and packaging solutions. Firstly, the main body of the drying rack features a detachable design, allowing it to be disassembled and packaged separately. This greatly reduces packaging volume while ensuring all components are well-protected. Secondly, the mesh spacers are also detachable, enabling the mesh panels to be neatly stored in custom cardboard boxes. This further minimizes overall volume and provides comprehensive protection during shipping.

This innovative design effectively prevents transportation damage, enhances handling convenience, and significantly reduces logistics costs.

you can see the result directly from packaging volume, as follow:

Packaging volume of Traditional Racks: 1.2 CBM

Packaging volume of New Racks: 0.4 CBM

Parameter

Shelf Size: 900x650mm / 35.43×25.6inch

Rack Size: 800x1000x1630mm / 31.5×39.37×64.17inch

Wire Diameter: 5x3mm

Layer quantity: 50 pcs

Wheel: 4 PC

Mesh hole: 100x130mm/ 3.94×5.12inch

Gap between layers: 25.4mm/1 inch

Package 1 for shelives: 97x67x28cm

Package 2 for main body: 108x74x14cm

Total Gross weight: 75kgs

Total volume:0.4 CBM

Warranty: 3 years

We send spare plastic spacer pads and install tools with racks.

Custom size and materials according to requirements

Shipping Machines & Supplies to Customers WorldwideWe will pack the goods in good condition before shipping, ensure that the goods arrive in perfect condition after long-distance transportationu003cbru003eHere are some real scenes of the shipment and packaging process.

Export screen printing machines to Spain

Export 24u0022x32‘’ exposure units to UK

Export 6KW flash dryers to amazon warehouse

Export IR conveyor tunnels to Germany

Printvs’Certification

Why Choose Printvs as Screen Printing Machine SupplierOur silk screem printing products have superior performance, strong reliability, and have been widely used in China and other countries and regions in Asia, America, Australia, Europe, Africa, and won the user high praise from users.

Machine Quality

After Service

Factory Scale

Prefect Warranty

Technical Support

Company Honor

Exhibitor at International Trade Shows/Fairs/ExhibitionsPrintvs take part in internaltional shows/exhibitions for many years

Exhibitor

Exhibitor

Exhibitor

Exhibitor

Exhibitor

Exhibitor

Exhibitor

Exhibitor

FAQs:

Q: How to choose a screen printing machines or other equipment?

A: You choose the screen printing machines according to your images,if your image have 4 color, you should choose the 4 color screen printing machine, if you want to improve the efficiency, you can buy flash dryer together.

Q: How about the installation?

Q: How about your delivery time?

Q: What about after-sale service?

Q: What mode of payment do you usually accept?

Q: How long is the warranty period for your equipment?

Q: How to choose the shipping way

Q: Do you customize aluminium frames or making screens

Q: How to choose the rright silk screen mesh size

Q: How to choose a screen printing machines or other equipment?

A: You choose the screen printing machines according to your images,if your image have 4 color, you should choose the 4 color screen printing machine, if you want to improve the efficiency, you can buy flash dryer together.